The workpiece deformation in machining is a difficult problem to solve. Analyzing the cause of the deformation is necessary before taking countermeasures. In general, there are four reasons in the following:

1. The material and structure of the workpiece will affect the workpiece deformation

The amount of deformation is proportional to the factors as below:

- the complexity of the shape

- the aspect ratio

- the wall thickness

- the rigidity and stability of the material

Therefore, it’s very important to minimize the influence of these factors on the deformation of the workpiece when designing the part.

2. The deformation caused by clamping

When clamping the workpiece, first select the correct clamping point and then adjust the appropriate clamping force according to the position of the clamping point. Besides, increasing the contact area between the workpiece and the clamp or adopting the axial clamping force, designing and manufacturing a special jig and fixture can make the clamping force act on the end surface, which can solve the bending deformation of the workpiece due to the thin thickness and poor rigidity of the workpiece.

3. The deformation caused by the workpiece processing

To Take corresponding measures, the correct selection of the tool is a necessary condition. The precision of the tool is required for finishing. On the one hand, the resistance formed by the friction between the tool and the workpiece can be reduced; on the other hand, the heat dissipation capability of the tool when cutting the workpiece can be improved, thereby reducing the residual internal stress of the workpiece. High-speed machining is also beneficial to ensure the size and shape accuracy of the parts.

In addition, the cutting fluid is mainly used to reduce the friction during cutting and to reduce the cutting temperature. Reasonable use of cutting fluid plays an important role in improving tool durability, machining surface quality, and machining accuracy.

The reasonable cutting amounts in machining is also a key factor in ensuring part accuracy. In the case of thin-walled parts with high processing precision, symmetric machining is generally adopted to equalize the stress generated on the opposite sides to reach a stable state.

4. Stress deformation after processing

The internal stress of the part itself is a relatively balanced state so that the shape of the part is relatively stable. Once the internal stress changes after processing, the workpiece needs to reach the balance of force again, so the shape changes. Solving such deformations can be corrected by heat treatment. After straightened by heat treatment, the internal structure of the workpiece is stable. At this time, the workpiece not only has better straightness but also the work hardening phenomenon is eliminated, which facilitates further finishing the part.

In summary, for the easily deformable workpiece, the corresponding countermeasures should be adopted in the blank and the machining processing. It is necessary to analyze according to different situations to find a suitable processing method.

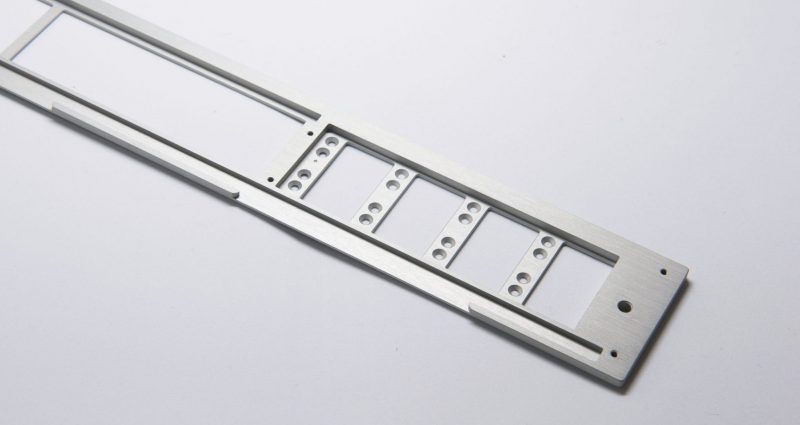

You can find the photo display of the CNC machining parts made by us HERE!