About Us

Our Records

99

SERVICED COUNTRIES

99

CLIENTS

99

PROJECTS PROCESSED

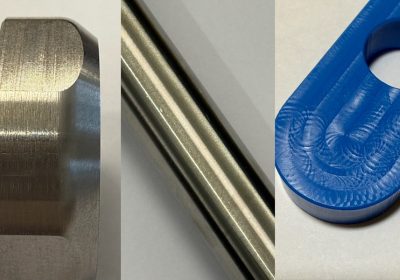

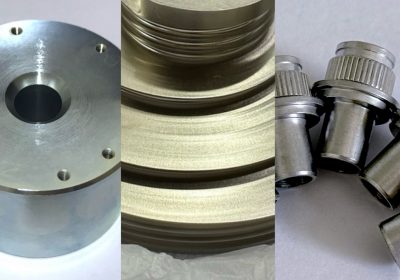

Our Machining Parts

Photo

RFQ Process

This is completed process of our CNC machining & stamping services. If you would like to understand about the details, please click each step to read more.

Quote

Please send below information to era@prochain-cnc.com

2D drawings (.pdf / .dwg / .dxf)

3...

Read More

Read More

Order

Once receiving official order released from customer, we will feedback Proforma invoice to customer ...

Read More

Read More

Sample / Mass production

Producing each item based on customer’s orders and drawings.You can find our core services: CNC lath...

Read More

Read More

Quality Inspection

Quality inspection is necessary for each production process, like IQC, IPQC(MQC) , FQC, OQC. And we ...

Read More

Read More

Delivery

We can provide air freight and sea freight according to the amount and gross weight of goods.

Air f...

Read More

Read More

Featured Articles

Brief Discussion on the Importance of Surface Roughness in CNC

2025-10-22

In CNC machining, machining accuracy primarily refers to the dimensional precision of a workpiece, while surface roughness refers to the quality of the outer surface of the machined object... Chrome, Zinc, or Nickel Plating: Which Is Right for Your Application?

2025-07-03

The electroplating process is widely used in industrial design. It forms different metal film layers on the surface of metal objects through the principle of electrolysis to provide variou... Essential Sandblasting Basics You Should Know

2025-03-27

What is Sandblasting?

Sandblasting is a technique that uses high-pressure airflow to spray abrasives onto the surface of an object to remove burrs, dirt, oxidation, coatings, or to adjust s... Partner with Prochain

Looking for high-quality CNC solutions? Contact us to discuss your project needs.