In recent years, people have found that the use of hexavalent chromium has caused great harm to the environment and the human body. With the rising awareness of environmental protection, the European Union issued the RoHS Directive (Restriction of Hazardous Substances Directive). The prohibition and restriction of hexavalent chromium toxic substances in such products have a great impact on the traditional surface treatment process using hexavalent chromium substances. At present, trivalent chromium treatment solutions are mostly used as an alternative. In order to comply with environmental directives such as RoHS, many countries around the world have banned the import of hexavalent chromium plating products.

How is Trivalent Chromium Plating Different from Hexavalent?

The main difference between trivalent chromium and hexavalent chromium is that in the process of trivalent chromium electroplating, the harmful substances produced are much lower than in hexavalent chromium electroplating, so trivalent chromium electroplating is also called environmental electroplating. The advantages of trivalent chromium plating include easy handling and reduced environmental pollution, so it has developed rapidly in recent years and has been put into production and application on a large scale, far exceeding the traditional hexavalent chromium plating.

Before the emergence of the EU RoHS directive, hexavalent chromium plating was used in a wide range of surface treatment technologies, including anodizing, electropolishing, and chemical conversion coating of many alloy metals such as aluminum, zinc, copper, etc.

Trivalent and Hexavalent Zinc Plating

As far as the machining industry is concerned, hexavalent zinc plating is one of the most commonly used electroplatings in the past. Since zinc is an active metal, if there is no proper after-treatment after zinc electroplating, the coating will quickly deteriorate. In order to reduce the activity of zinc, a chromate solution is often used for passivation treatment, so that a layer of chromate conversion film is formed on the surface of the zinc layer.

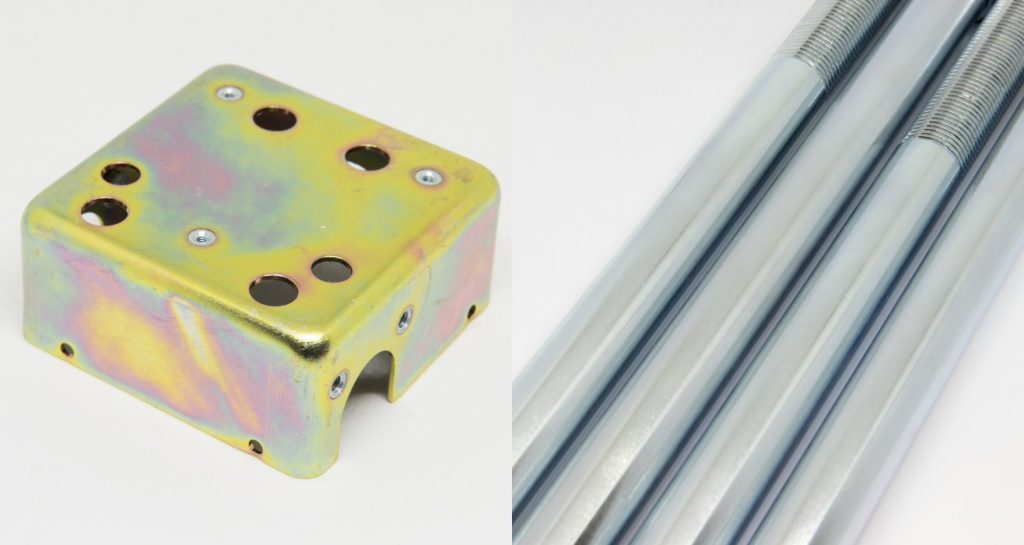

This passivation film is actually a compound after a redox reaction between trivalent chromium, hexavalent chromium and zinc. Among them, the compound of trivalent chromium and zinc is blue-green, and the compound of hexavalent chromium and zinc is red ochre or brownish yellow. As a result of the combination and mutual interference of different pigments, a passive film with beautiful shades of iridescent colors is formed.

Trivalent chromium compounds are generally insoluble in water and have high strength, while hexavalent chromium compounds are easy to dissolve in water, especially in hot water. It is attached to trivalent chromium compounds and has the function of self-repair. When the passivation film is damaged, in the air with a certain humidity, the hexavalent chromium compound dissolves in water to form chromic acid, which can continue to react with the zinc layer to form a passivation film again. This is why some trivalent chromium galvanized coatings are less corrosion resistant than hexavalent chromium galvanized.

Under the impact of the RoHS directive, the traditional surface treatment process has been challenged. Clients will also strengthen the green supply chain system through RoHS, WEEE, and EuP treaties, etc. We always pay attention to the latest news of international norms and try our best to achieve the requirements of clients and sustainable development.

You can find the photo display of the CNC machining parts made by us HERE!