The methods of processing threads on the workpiece mainly include cutting and rolling. The purpose is to make the corresponding bolt or nut can be matched. Commonly used cutting processing methods include turning thread and tapping, and rolling processing methods include flat die thread rolling and roller die thread rolling.

When determining a thread processing method, there are many factors to consider. The main ones are the specification of the thread, the tolerance of the thread, the shape of the workpiece, the characteristics of the workpiece material, and the production method. We will introduce 4 common thread processing methods as following:

Cutting processing

Most of the thread processing is done directly on the CNC machine, which is a common method for single-piece and small-volume production of threaded workpieces.

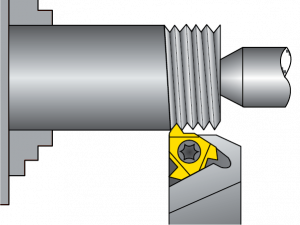

1. Turning thread

It refers to the method of machining thread on a workpiece with a forming cutter. When threading, the transmission chain of the CNC machine ensures that the turning tool moves along the axis of the workpiece accurately and evenly for each revolution of the workpiece. So that the cutting tool and the workpiece rotate relative to each other to form thread grooves.

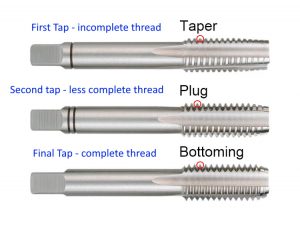

2. Tapping

Tapping is to use a certain torque to screw the thread tapping tool into the pre-drilled through hole or blind hole on the workpiece to process the internal threads. The accuracy of tapping depends on the tapping tool. Generally, small-diameter internal thread is mostly processed by tapping. It is the most widely used thread processing method in CNC turning and milling machines.

Rolling processing

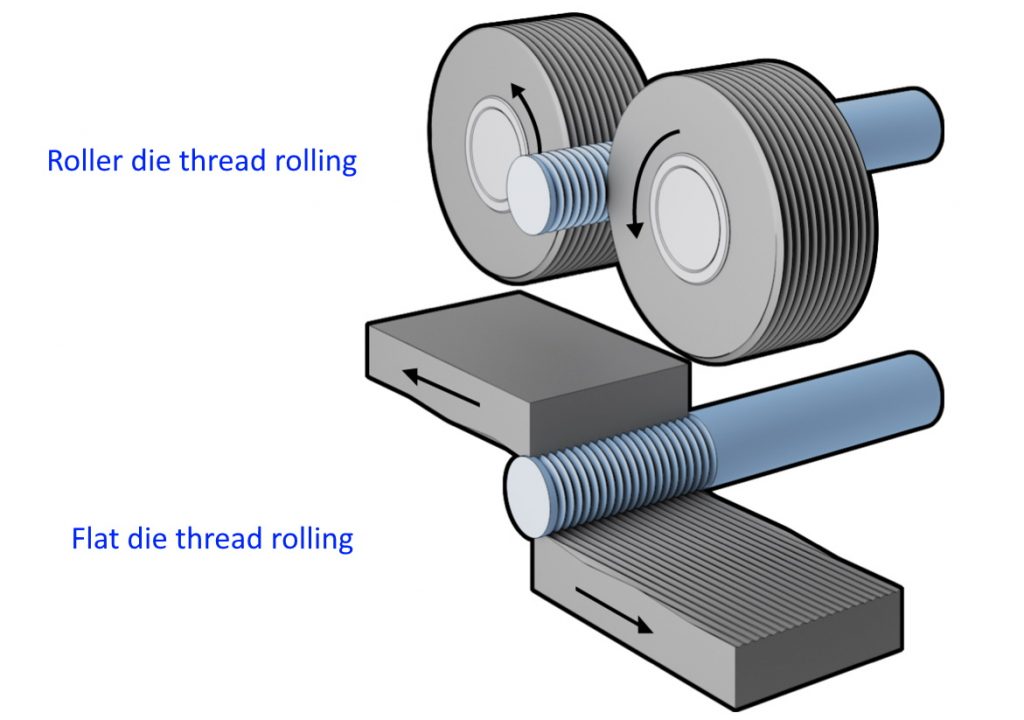

The processing method of using a forming rolling die to plastically deform a workpiece to obtain thread. It is suitable for mass production with a large amount of externally threaded fasteners. According to the different rolling dies, it can be divided into two types: flat die thread rolling and roller die thread rolling.

3. Flat die thread rolling

Two flat thread rolling dieas are arranged relative to each other with a staggered pitch. One flat die is fixed, another flat die makes a reciprocating linear motion parallel to the fixed flat die. When the workpiece is fed between the two dies, the movable die advances and rubs the workpiece to plastically deform its surface into a thread.

4. Roller die thread rolling

The most common ones are radial rolling and thread rolling head (for CNC lathe machine)

-Radial rolling

2 threaded rolling wheels are installed on parallel shafts, the workpiece is placed on the support between the two wheels. The two wheels rotate in the same direction at the same speed. One of the rounds also makes a radial feed movement. The workpiece rotates under the drive of the thread rolling wheel, and the surface is squeezed radially to form a thread.

-Thread rolling head

It is carried out on CNC lathe machines. It is generally used to process short external threads on a workpiece. The rolling head has 3 to 4 thread rolling wheels evenly distributed on the outer circumference of the workpiece. During thread rolling, the workpiece rotates and the rolling head feeds axially to roll the workpiece out of the thread.

The advantages of rolling processing compared with cutting processing are:

- The surface roughness is less than cutting processing.

- The thread surface after rolling can improve the strength and hardness due to cold work hardening.

- The material utilization rate is high. The productivity is doubled than the cutting process, and it is easy to realize automation.

- The rolling die has a long life. But there are certain restrictions on the hardness of the workpiece material.

- Higher requirements for the dimensional accuracy of the die;

- The precision and hardness requirements of rolling molds are also high. So manufacturing molds is difficult;

- It is not suitable for rolling thread with an unsymmetric thread profile.

To summarize the above, tapping refers to threading the inner wall of a through hole or blind hole to manufacture internal thread. Thread rolling is the processing of cylindrical workpiece surface to manufacture external thread. Turning thread can be processed both internal thread and external thread.

When it comes to choosing thread processing, you can consider which thread processing method is most suitable according to the quantity, accuracy, machine equipment, and cost.

You can find the photo display of the CNC machining parts made by us HERE!