Springs are parts made of elastic materials into special shapes. When subjected to an external force, it can be stretched, contracted or deformed in other different ways to absorb the external force and be stored in the body. After the external force is removed, the energy originally absorbed and stored in the body is released and restored to its original shape. This is the feature of springs.

The functions of springs

- Absorb vibration and relieve shock

such as springs of the chassis of cars or trains, springs on landing wheels of airplanes, buffers on brackets of locomotives, etc. - Force measurement or power indication

such as springs on spring scales and various power indicators. - Generate force to maintain mechanical contact

such as boiler safety valves, brakes, clutches and springs on cam mechanisms. - Energy storage

such as clockwork and gun trigger.

Springs have a variety of different types and corresponding functions. They are roughly divided into two categories: linear springs and leaf springs (shrapnel). The most common one is linear springs. The cross-section of the linear spring is often made of round or other shaped metal wires. Because it is often made into a spiral shape, it is also called helical springs. The different force properties can be divided into three types: compression spring, extension spring and torsion spring:

1. Compression spring

Compression spring is the most common spring type. There is a sufficient gap between each coil of the spring, which can be shortened after being pressed. It will return to its original length when the external force disappears. It is usually divided into an open coil and a closed coil. In order to increase the contact area of the two ends of the spring under pressure and to prevent the spring from bending and deforming, the two ends of the spring are often ground flat to obtain more contact area. Usually used in safety valves, automobile valve springs, wheel shock absorbers, and ballpoint pen assembly.

2. Extension spring

Extension spring stretches after being stretched by an external force and returns to its original shape when the external force disappears. Generally, the coils of the spring are wound into a spiral shape and the coils are close to each other. Each end of the extension spring has a hook for hanging, the direction and angle of the hook can be adjusted during production. It is usually used in stretching exercise equipment, brake pedals, and return springs for drum brakes.

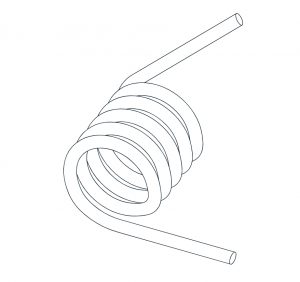

3. Torsion spring

There are two types of torsion springs. One is the helical torsion spring, which uses the torsion force of the radial axis to control the parts, such as grip exercisers and automatic screen door closer. The second is the spiral torsion spring. It is used as the clockwork as the driving power source in the clock mechanism.

Basic springs nomenclature and information

Material:

The general spring material is mostly metal, such as piano wire (SWP), spring steel (SUP), stainless steel, copper (pure copper, brass, beryllium copper), etc.

Wire diameter (d):

The diameter of the steel wire used.

Outer diameter (Do):

The maximum diameter of the spring coil.

Inner diameter (Di):

The smallest diameter of the spring coil.

Mean coil diameter (Dm):

The average value of the outer diameter and inner diameter of the spring coil.

Total number of coils (Nt):

Refers to the sum of active coils and closed coils.

Active coil number (Na):

The number of coils in the spring that can effectively respond to deformation. It should be at least 3 turns, otherwise, the spring characteristics will be unstable.

Rotation:

General springs are right-handed, and left-handed springs are rare.

Free length:

The length of the spring under completely unloaded conditions.

Heat treatment:

Springs usually need to be tempered for stress relief.

With the above data information, a practical spring can be designed and processed according to requirements.

You can find the photo display of the CNC machining parts made by us HERE!