Generally speaking, cold working and hot working are distinguished by the temperature state of the production process. The process that does not cause chemical changes at room temperature is called cold working, and the process that causes chemical and phase changes at a temperature higher than room temperature is called hot working. In addition, the processing characteristics of the two are also different.

Cold working of metal usually refers to the cutting of metal. Cutting tools (including abrasive tools and abrasives) are used to cut the excess material layer on the blank or workpiece so that the workpiece can obtain the specified geometric shape, size and surface quality. Such as turning, milling, drilling, grinding, etc.

Even though the precision of blank manufacturing continues to improve and widely used, such as precision casting, precision forging, extrusion, powder metallurgy, metal injection molding and other processing technologies. But due to the cutting processing can achieve high precision and better surface roughness, it still occupies an important position in the mechanical manufacturing process.

In metallurgy, the processing below the metal recrystallization temperature is called cold working. It refers to the processing technology that plastically deforms the metal below the recrystallization temperature, such as cold rolling, cold forging, cold extrusion, stamping, etc. Cold working improves the strength and hardness of the metal through work hardening while forming the metal.

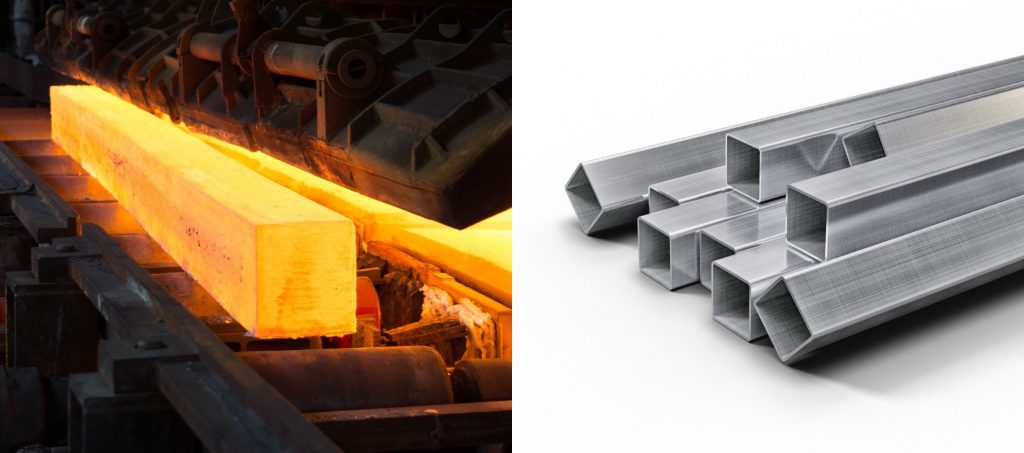

In contrast to cold working, hot working is generally referred to as processing above the metal recrystallization temperature. It can be divided into metal casting, welding, hot rolling, hot forging, and metal heat treatment:

- Casting and welding are the melting and solidification of the metal.

- Hot rolling and forging are to heat the metal to the stage of plastic deformation and then perform forming processing.

- Metal heat treatment only changes the metallographic structure of metal parts, including annealing, normalizing, quenching, tempering, etc.

Hot working can improve the structure of metal parts while forming, or change the crystalline state of formed parts to improve the mechanical properties of the parts. It has wide adaptability and large process flexibility. Metal materials commonly used in industry can be used for hot working to produce parts with complex shapes, especially parts with complex cavities.

In fact, the fundamental reason to distinguish between cold processing and hot processing is that different mechanical parts have different processing requirements (such as shape, precision, etc.), and they all have specific and suitable processing methods. Therefore, in the production of mechanical parts, it is necessary to analyze and formulate the mechanical processing methods of the parts in order to effectively increase the processing productivity at a reasonable cost.

You can find the photo display of the CNC machining parts made by us HERE!