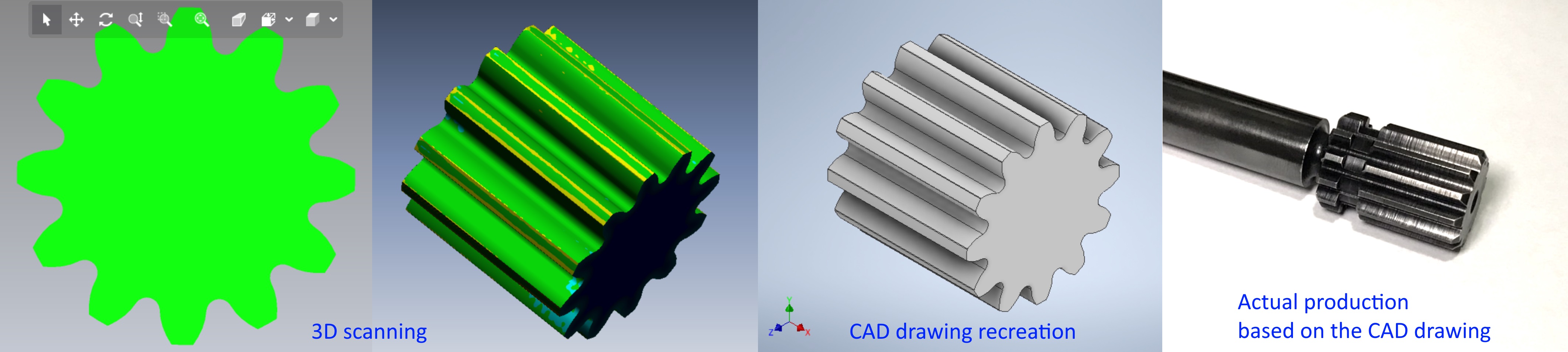

Recently, we dealt with a special requirement for gear processing. Considering that manufacturing gears only based on the drawing data may cause some deviation in actual application, we suggest our client provides gear samples for reverse engineering. On the one hand, we can check the dimensions in the drawing, and on the other hand, we can ensure that the processed gear can be used by clients without any issue.

However, what is “reverse engineering”?

There are physical objects or models on hand that require 3D printing, CNC remodeling, or mold-opening production, and the action of recreating the actual product from the actual product is called reverse engineering.

There are roughly two steps in reverse engineering:

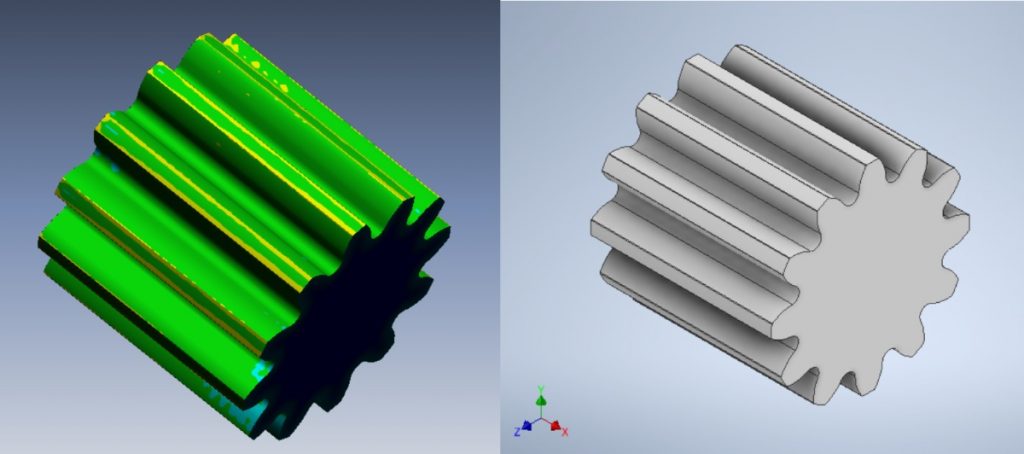

1. 3D scanning

The model surface and dimensional data scanned by the 3D scanner.

2. CAD drawing recreation

According to the result of 3D scanning, redrawn through software to create CAD or CAM files and use it in manufacturing.

Reverse engineering is a processing application method commonly used today. Through 3D scanning reverse engineering, it can effectively shorten the time of drawing and checking dimensions/specifications. In addition, it also can reduce the time and money cost of design adjustment and optimization. It is helpful to assist clients in research and development for product design.

If you have any questions and inquiries about reverse engineering, please do not hesitate to contact us for a discussion.

Also, You can find the photo display of the CNC machining parts and stamping parts made by us through the link.