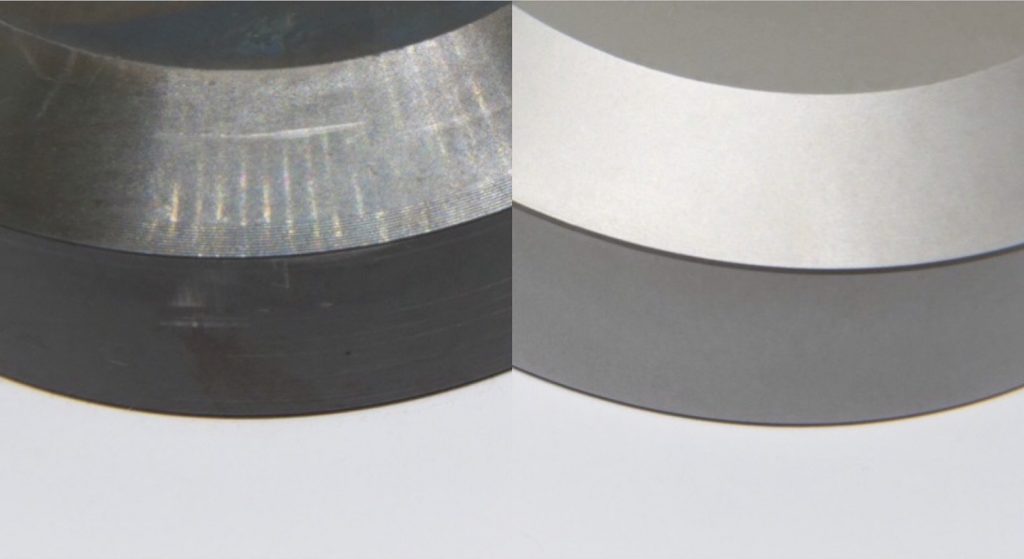

Recently, we processed a stainless steel 400 series part and encountered the problems of poor surface quality with serious surface oxidation after heat treatment. We switched to do vacuum heat treatment to make the finished product meet the needs of clients regardless of hardness and aesthetics.

Vacuum heat treatment is that all or part of the heat treatment process is performed in a vacuum state. It can realize almost all heat treatment processes that can be involved in conventional heat treatment, such as quenching, annealing, and tempering, carburizing, nitriding, but the quality is greatly improved.

Compared with conventional heat treatment, what are the advantages of vacuum heat treatment? It can be summarized in the following points:

No oxidation, no decarburization, no carbonization, good protection for the inside and surface of the workpiece

Oxidation might cause below issues:

- The metal surface loses its metallic luster

- Increasing surface roughness

- Decreasing precision

- Decreasing the strength and other mechanical properties of steel material

- The oxide layer on the steel surface is often the source of quenching soft spots and cracks.

Decarburization refers to the phenomenon that the surface carbon content of steel decreases when heated. In general, oxidation and decarburization are carried out at the same time. As the decarburized layer is oxidized, the reduction of carbon content will significantly reduce the quenching hardness, wear resistance, and fatigue performance of the steel.

In vacuum heat treatment, since the metal is heated under a certain degree of vacuum, the workpiece avoids contact with oxygen. The workpiece is not oxidized and no decarburization. Therefore, a bright surface and good heat treatment quality can be obtained.

Improve the overall mechanical properties, degas and promote the purification of metal surfaces

The vacuum also has a good effect of eliminating dissolved gases in solid metals. The most harmful gas in metals is hydrogen. When vacuum heating is used, the hydrogen in metals and alloys can be quickly reduced to a minimum. The situation of hydrogen embrittlement could be eliminated. Thereby improving the overall mechanical properties of the workpiece like plasticity, toughness, and fatigue strength.

When metals and alloys are heated in a vacuum, the oxide will decompose, and the formed free oxygen is immediately discharged from the vacuum chamber. It further improves the quality of the metal surface and plays a purification role.

Small deformation of the workpiece

In general, the workpiece to be processed is heated by heat radiation in the furnace. The temperature difference between the inside and outside is small, and the thermal stress is small. Therefore, the deformation of the parts treated by the vacuum heat treatment process is small. It can avoid man-made processing deformation caused by handling the workpiece in the hot state.

Environmental advantages

Besides the advantages of doing vacuum heat treatment for metal and workpiece as above, there are also some environmental advantages of using vacuum heat treatment furnace:

- High thermal efficiency, which can rapid heating and cooling.

- Good stability and repeatability.

- The operation is safe.

- The working environment is no pollution.

If you have any questions and inquiries about heat treatment, please do not hesitate to contact us for a discussion.

Also, you can find the photo display of the CNC machining parts made by us HERE