1. Quenching

Quenching is a treatment in which the metal is heated to the transformation temperature and then quenched, such as being placed in water or cooled in oil to make the crystal grains fine and the hardness becomes high. After quenching, the metal material becomes hard and brittle. In order to prevent brittle cracking of the hardened steel, it is subjected to a tempering process.

Because the metal has residual stress during the quenching process, the re-heated and quenched parts are oil-cooled or air-cooled below the transformation temperature. So that the residual Austenite structure can be converted into a Martensite structure. It can avoid the residual stress that causes brittle fracture of the metal after quenching.

2. Tempering

The quenched steel is heated to below the transformation temperature of austenite and cooled for 1 to 2 hours to reduce the brittleness caused by quenching. The structure of the steel tends to be stable, and the toughness and plasticity are improved. Tempering and quenching are often referred to as thermal refining.

3. Annealing

The metal by casting, forging, or cold-rolling will produce a hardness that is difficult to process. It means strain energy generated by cold-forming remains in the metal and causes dislocation. Therefore, annealing is a method of heat treatment to reorganize the structure of crystal grain. The metal is heated to above the transformation point and maintained at this temperature for a while and slowly cooled in the furnace.

The purpose of annealing is as below:

- Homogenize the interior of the material

- Soften the material

- Eliminate internal stress

- Adjust the structure of crystal grain

- Spheroidize carbides for easy processing

For example, the original steel can be ground with a file. After hardened by quenching, the steel can not be ground and even the file will be damaged. Once the quenched steel is annealed and returned to the original steel characteristics, the steel can be ground with a file again. It can be seen that heat treatment has a considerable influence on material application and machining.

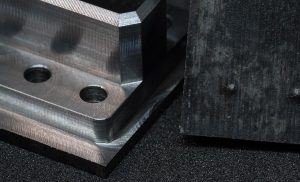

You can find the photo display of the CNC machining parts made by us HERE!