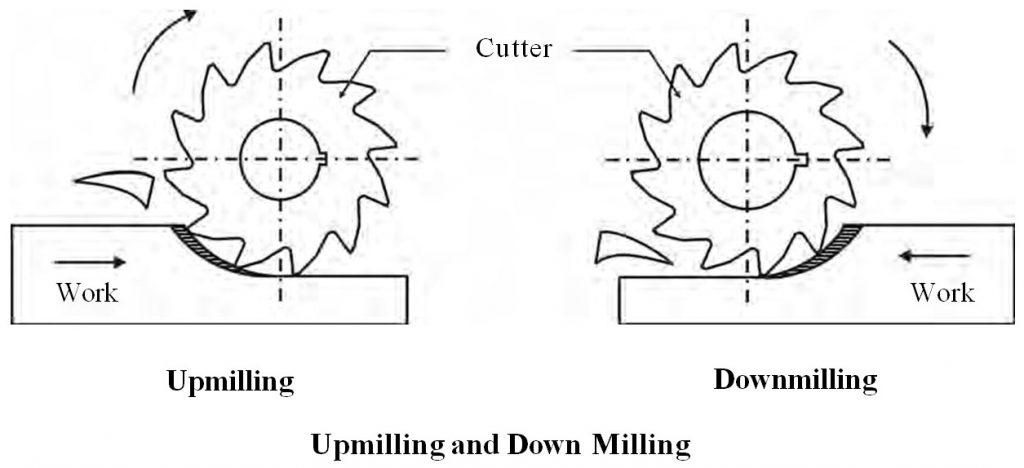

Milling is one of the most common types of machining methods. For roughing or finishing parts of different structures, it is mostly done by end milling. According to the moving direction of the cutting edge and the workpiece is opposite or the same, it is divided into up-milling and down-milling.

Up-milling

The milling direction and feeding direction are in the opposite. The chip is generated from bottom to top (from thin to thick). This method is also called conventional milling. The features of up-milling:

- The force of the milling cutter starts lightly and ends heavily, which can avoid the tool from being broken by the impact.

- Suitable for milling rough surfaces.

- Can be used in old milling machines without the ineffective gap movement of the screw.

- More friction, easy to blunt knife edge and short life.

- Easy to machining, but with rough processing surface and poor processing accuracy.

- The device is not easy to be assembled and is not suitable for milling thin parts.

- It consumes more energy.

Down-milling

The milling direction is the same as the feeding direction. The cutting effect is caused downward from the unmachined surface (from thick to thin). The features of down-milling:

- The force of the milling cutter starts heavy and ends lightly, which is easy to have an impact on the tool and break the blade.

- Not suitable for the surfaces of castings and forgings.

- The milling machine must have a gap elimination device, otherwise, it will easily produce the ineffective gap movement of the screw.

- Less friction during machining and the longer life of tool edge.

- Easy to clamp, no vibration, high precision of the machined surface.

- Easy to install, suitable for milling long and thin workpieces.

- The feeding rate consumes less energy.

You can find the photo display of the CNC machining parts made by us HERE!