In CNC machining, machining accuracy primarily refers to the dimensional precision of a workpiece, while surface roughness refers to the quality of the outer surface of the machined object. It is a quantitative term for geometric parameters of the machined surface and is measured in grades. The smaller the grade, the higher the precision. Commonly used specifications include Ra and Rz.

The following are surface roughness values corresponding to several common machining methods for reference:

Lathe/Turning

As the workpiece rotates, the turning tool moves in a straight or curved path within a plane. Turning is typically performed on a lathe and is used to machine internal and external cylindrical surfaces, end faces, conical surfaces, formed surfaces, and threads. The surface roughness achieved by turning is generally between Ra 1.6 and 0.4.

1) Rough turning strives to improve turning efficiency by using a large depth of cut and high feed rate without reducing cutting speed. The surface roughness is over Ra 12.5.

2) Semi-finishing and finishing turning utilize high speeds with minimal feeds and depths of cut, achieving a surface roughness of Rα12.5-0.2μm.

3) High-speed finishing turning using a finely ground diamond turning tool on a high-precision lathe achieves a surface roughness of Rα0.2-0.01μm. This type of turning is called “mirror turning.”

Drilling

Drilling is a basic hole-making method, commonly performed on drilling machines and lathes. Drilling has low machining accuracy, with surface roughness typically ranging from Ra 12.5-3.2.

After drilling, reaming and boring are often used for semi-finishing and finishing to achieve even better surface roughness.

Milling

Milling involves cutting workpieces using a rotating multi-edge tool. It is a highly efficient machining method. It is suitable for machining flat surfaces, grooves, various formed surfaces (such as splines, gears, and threads), and special mold surfaces.

Milling is categorized as either down-cut milling or up-cut milling, depending on whether the main motion direction is aligned with or opposite to the workpiece feed direction.

Milling typically achieves a surface roughness of Ra 3.2–0.8.

1) Rough milling achieves a surface roughness over Ra 6.3.

2) Semi-finish milling achieves a surface roughness of Ra 1.6-6.3.

3) Finish milling achieves a surface roughness of Ra 0.8-1.6.

Surface quality in CNC machining is positively correlated with surface roughness. Achieving good surface roughness can be discussed in several key areas:

1. Material Properties

The hardness and ductility of the material itself also affect the final surface roughness.

2. Tool Condition Inspection

Wear or damaged tools increase friction and heat, which in turn affects surface roughness. Therefore, regular tool maintenance and replacement, ensuring tools are sharp and free of nicks and damage, will achieve better surface finish.

3. Adjusting Cutting Parameters

These parameters, including spindle speed, feed rate, and depth of cut, directly affect surface roughness. Optimizing these parameters can help reduce excessive cutting forces that can negatively impact the finished surface. For example, excessively high feed rates can generate excessive heat and pressure, leading to deformation of the machined part.

4. Cutting Cooling

Lack of proper coolant injection can increase friction and potentially affect machining results. Ensure that coolant is continuously and properly applied to the cutting area.

5. Machine Rigidity

Insufficient machine or workpiece rigidity can cause vibration, making it difficult to achieve smooth output, significantly impacting surface quality and resulting in worse surface roughness. Check the rigidity of the machine and clamping device to ensure secure fixation. It is also crucial to use tools suitable for the machine and workpiece material.

Finally, let’s discuss the effects of surface roughness on workpieces:

1. Consumption

Rough surfaces increase friction, requiring more power to overcome resistance during assembly and use, increasing energy consumption.

2. Service Life

Workpieces with high surface roughness are more prone to stress concentration points. These areas are more susceptible to cracking under stress, shortening the workpiece’s service life.

3. Corrosion Resistance

A smooth surface reduces the presence of microcracks and pores, which can easily become the starting point of corrosion. Better surface roughness helps improve the corrosion resistance of the workpiece and extend its service life.

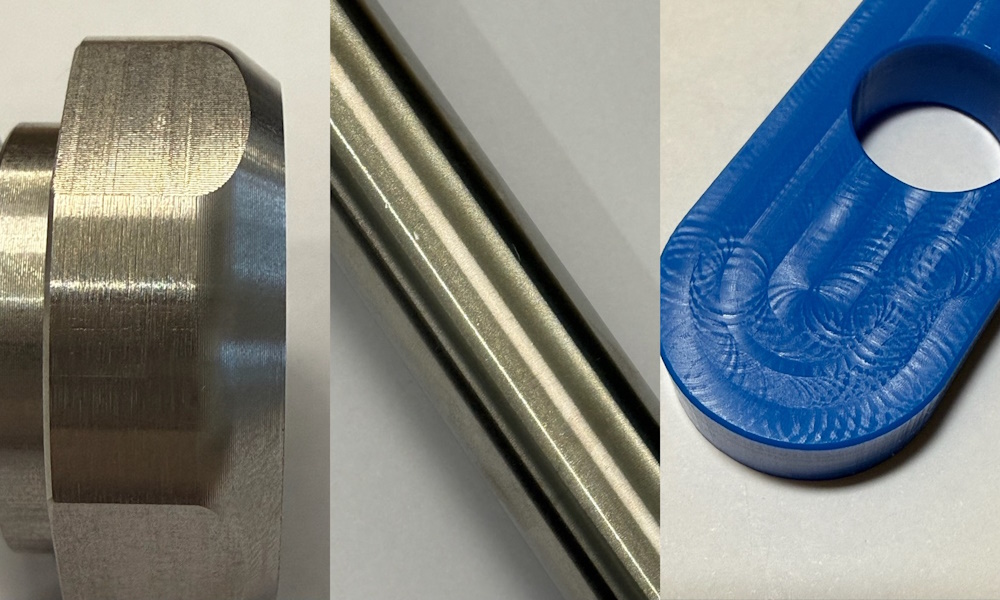

You can find the photo display of the CNC machining parts made by us HERE!