There is a thorny problem in the processing industry: How does metal effectively deburr? In particular, it is a headache to require a relatively high internal hole deburring and cross-hole deburring. Using ordinary mechanical deburring can easily produce secondary burrs or even scratches on products with lower hardness. So what kind of deburring method should I choose? Let’s analyze some of the main deburring methods.

1. Manual deburring

The operator uses a tool such as a file, sandpaper, and a grinding head to polish the workpiece and remove the burr. This method is not very technically demanding for workers. It is suitable for products with small burrs and simple product structure. Therefore, it is also a method for deburring commonly used in general enterprises. The file is divided into two types: manual file and pneumatic file. Manual files are more expensive, deburring efficiency is not very high, and it is difficult to remove burr in complex cross-holes.

2. Die deburring

The burr is removed by making a die with a punch.

Deburring of the die requires fine blanking die making, and it may be necessary to make a forming die. For products with simple parting surface, the efficiency and effect of deburring are better than the manual method.

3. Grinding deburring

Grinding deburring is a method of removing burrs by vibration, sandblasting, roller, etc., and is currently widely used by enterprises. The problem with grinding deburring is that sometimes the removal is not very clean. It may require subsequent manual handling or other methods of deburring. This method is suitable for small size products with large amounts.

4. Ultrasonic deburring

Ultrasonic deburring is a processing technique that uses ultrasonic energy to deburr. When the energy generated by ultrasonic waves acts on a liquid in a sparse state, it will tear into lots of small holes (the inside of holes are vacuum). When the holes are broken, it will produce an instantaneous pressure of up to several hundred atmospheres, and this phenomenon is called “Cavitation”. Ultrasonic deburring is the use of “Cavitation” to remove the burrs attached to the parts.

This processing method is mainly applied to some special surfaces like the complex mold cavity and deep hole surface that the normal deburring method is difficult to achieve. Using ultrasonic vibration machines with superabrasive (diamond or cubic boron nitride, etc.) generates energy to remove burrs with high efficiency and high precision.

5. Magnetic grinding machine deburring

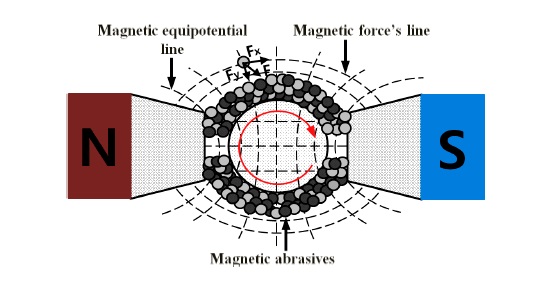

A magnetic field is added between the workpiece and the magnetic pole, and the magnetic abrasive is placed in the magnetic field. The magnetic abrasive is arranged in an orderly manner in the magnetic field to form a magnetic brush having certain flexibility. During the processing, the workpiece rotates while axially vibrating, and moves relative to the magnetic pole. The magnetic abrasive can remove a very thin layer of metal and burrs on the surface of the workpiece, and gradually flatten the surface to achieve a good grinding effect.

Magnetic grinding can complete the surface and inner hole deburring of the precision parts in one time and achieve high brightness without affecting the precision of the workpiece. It is suitable for grinding the inside and outside of parts, removing the burrs, chamfering, polishing, washing, etc. All processes will be completed in a few minutes and done once. Such as stainless steel screws, CNC turning and milling machining parts, alloy die-casting, stamping shrapnel, springs, hard plastics parts, etc.

You can find the photo display of the CNC machining parts made by us HERE!