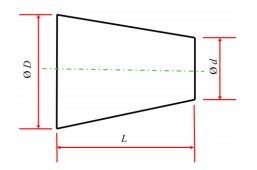

To make the inner and outer taper with the same taper angle for fitting, the friction resistance is combined with the two parts, and the two parts are kept in line.

There are five methods for the taper turning process by lathe machine on the following:

- Tailstock offset (suitable for long-axis workpieces and automatic feed turning)

Offset volume of the tailstock = (taper value * total length of the workpiece) / 2 - Multi-tool holder offset (larger angle and shorter length workpiece)

The X-axis lateral and Y-axis longitudinal handwheels are simultaneously feeding, but they are not accurate. (for the chamfer which does not require precision) - Taper turning accessories (like copying lathe, suitable for mass production)

- Forming tool (like chamfering tools)

- CNC lathe turning (by programming)

The fastest and the most precise method for machining.

You can find the photo display of the CNC machining parts made by us HERE!