Simply speaking, the principle of 3D printing is made by using special materials and layering stacking, commonly known as additive manufacturing. The CNC machining principle is to cut and process the entire piece of material into a specified shape of the product, also known as reduced material manufacturing.

There is much difference between 3D printing and CNC machining as following:

1. Different materials

Generally, most materials CNC can be processed. Like plastic materials (ABS, acrylic, PP, PC, POM, nylon, bakelite, etc.) and hardware materials (aluminum, brass, copper, steel, iron, etc.)

Currently, 3D printing (SLA) processing materials, the photosensitive resin is the most common.

2. Different material utilization rates

3D printing, due to its unique additive manufacturing, the material utilization rate is extremely high.

CNC machining, due to the need to cut the entire piece of raw material, and then get the final product, so the utilization rate of CNC processing materials is not high.

3. Processing comparison

Program:

3D printing: The built-in driver software automatically calculates the printing time and consumables.

CNC machining: requires professional programmers and operators.

Quantity of processing:

3D printing: As long as the tray is sufficient, multiple parts can be printed at one time without a manual guard.

CNC machining: Only one part can be machined at a time.

Processing time:

3D printing: Since 3D printing is formed once, the printing time is fast.

CNC machining: programming, processing time is longer than 3D printing.

Process complexity:

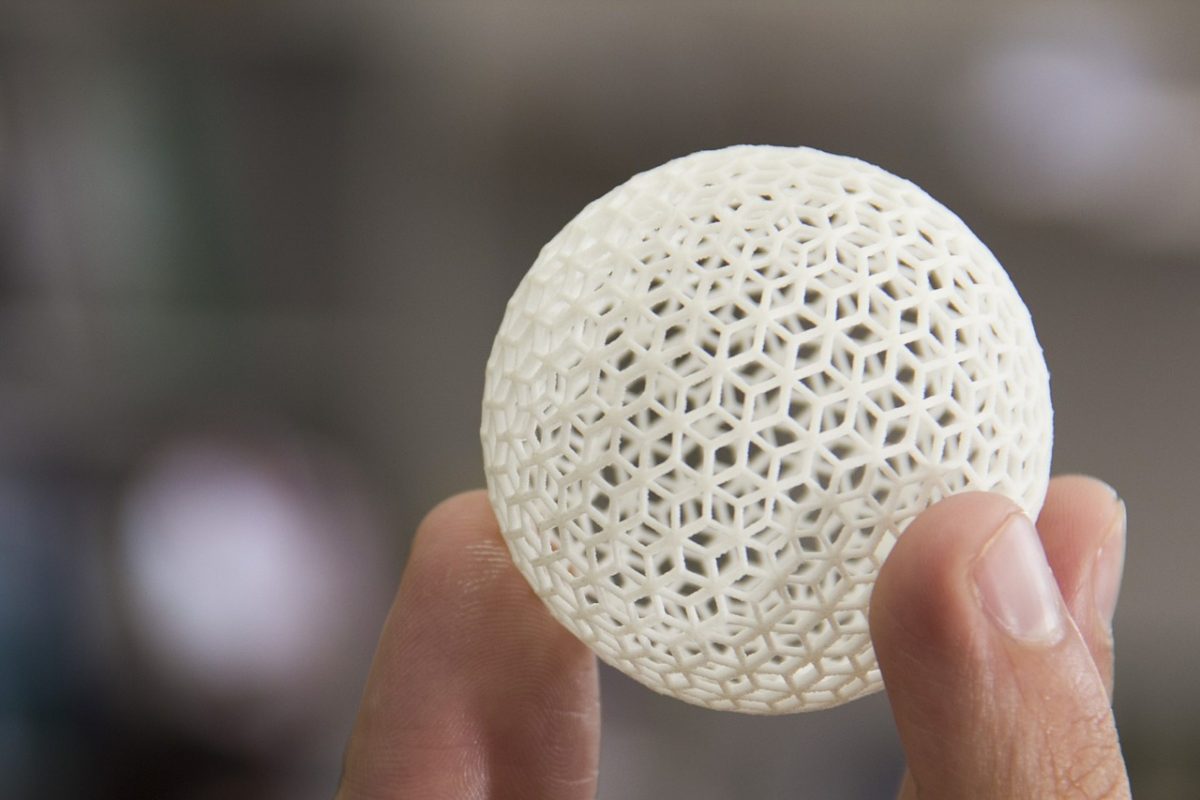

3D printing: parts that can process complex surfaces and structures by formed

CNC machining: parts with complex surfaces and structures need to be programmed multiple times and disassembled.

Different precision and success rate:

3D printing: WYSIWYG (What You See Is What You Get), high printing accuracy, and high success rate.

CNC machining: There are cases where human error or poor fixture causes processing failure.

4. Product usability

3D printing: The molded product has the disadvantages of low strength and less wear resistance.

CNC machining: molded products have the advantages of high strength and wear resistance.

Why is CNC machining still the first choice for business?

In the above comparison, 3D printing seems to have more advantages than CNC machining, but in actual situations, why is CNC machining still the preferred process for enterprises? The reasons are as follows:

Economic advantage

When processing large and heavy parts, CNC processing prices are much cheaper than 3D printing.

Processing standards

CNC machining has evolved over a long period of time and a complete set of standards has been developed in the industry, including spindles, tools, and control systems. However, there is currently no such molding standard for 3D printing.

Awareness

Many companies are completely unfamiliar with 3D printing. Because they are unfamiliar and do not trust this process, they often choose CNC machining that they are familiar with and understand when they face the choice.

You can find the photo display of the CNC machining parts made by us HERE!