Polishing material rod

Polishing material rods are made by cold drawn. The surface roughness of raw material rods can be Ra1.6 to Ra3.2. And the roundness can be within 0.1mm. They are commonly used due to customer’s requirement for surface roughness and quality.

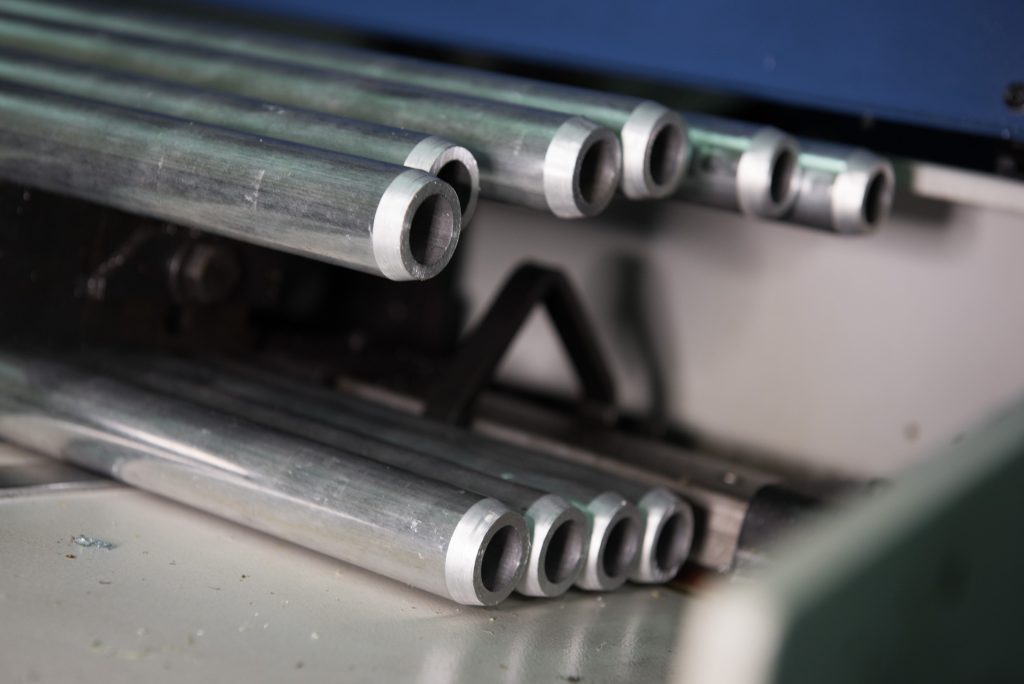

Tube matreial

Using solid rods or hollow tubes materials for machining is depending on the depth of holes. If the hole is through the whole part, hollow tube materials will be better for production. However, most of tube materials have to be specialized made with minimum order quantity (MOQ). If there are not tube materials with suitable dimensions in stock, or the customer’s order quantity is not enough, solid rods still the primary option for production.

Cutting raw material

In CNC milling machining, the raw materials have to be cut to bulks or strips with appropriate dimensions before production. In this way, the machining time and waste can be reduced. It is also benefit with production efficiency and capacity utilization rate improvement.

CNC programming design

CNC programming (Computer Numerical Control Programming) is utilized to create program instructions for computers to control machine tools, such as lathes, mills, and cutters. CNC machines are controlled entirely by software, and along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis and improves automation as well as flexibility.